This type CO removal catalyst completely converts CO at room temperature (≥15 ℃), Gas humidity ≤90%, space velocity (13) × 104 hours-1, and the residual CO content is ≤5ppm. It's mainly used for rescue chambers / refuge chambers, ships, gas masks, fire masks, CO2 lasers, and gas showers occasion.

- Operating temperature: ≥15℃

- Gas humidity: ≤90%

- Size: Ø2~3mm

- Pd content: 2.5%

- Bulk density: 800±50g/L

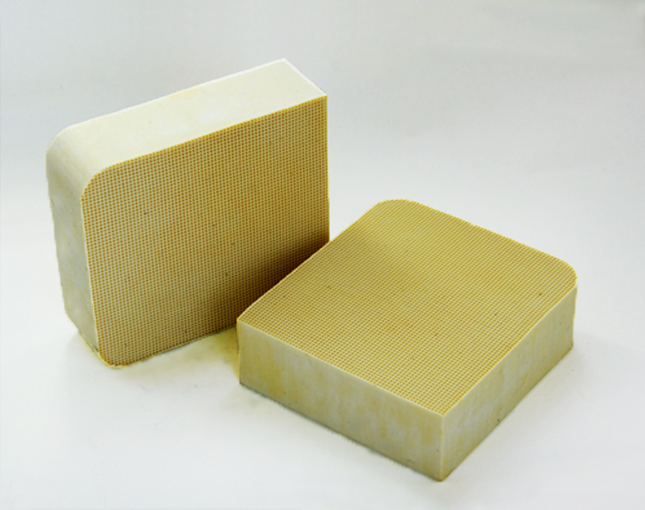

Hopcalite catalyst use copper oxide and manganese dioxide as main raw materials. It has a good catalytic oxidation effect on CO in a dry environment (room temperature and atmospheric pressure). It is mainly used for gas masks, mine self-rescuers, rescue capsules and other devices that need to remove carbon monoxide.

- Mn and Cu Effective Constituent: 80% min

- Surface Area: 180㎡/g min

- Strength: 18-20 N/cm

- Moisture: 3% max

- Type: Powder, Columnar Pellet, Granular Particle Size

This type CO removal catalyst can be used to remove CO under the conditions of temperature 150-200 ℃ and space velocity (0.3-1) * 104h-1, the carbon monoxide content of the purified gas can be reduced to below 0.5ppm. It's used to remove CO from petro gas, inert gas, oxygen and oven, chimney place, incinerator.

- CO removal rate: ≥98%

- Optimal service temperature: 180-200°C

- Service life: ≥ 2 years

- CO outlet content: <5ppm

- Bulk density: 0.68±0.05g/mL

This type CO removal catalyst is targeted at the exhaust treatment of fireplaces and ovens, under the temperature of 250 ~ 400 ℃ and space velocity (0.3~1) × 104h−1, the content of CO and CnHm can be reduced below 4mg/m3. It can be reused repeatedly, has good mechanical strength, and has a service life of more than 2 years.

- CO removal rate: ≥98%

- Optimal service temperature: 250-400°C

- Service life: ≥ 2 years

- CO outlet content: <5ppm

- Bulk density: 0.66±0.05g/mL