Thermal Power Exhaust Treatment

The flue gas from coal-fired boilers in thermal power plants is the most important source of pollution in the power industry. Pollutants in the flue gas produced by boiler combustion include fly ash, SO2, NOx, CO, CO2, a small amount of tritium fluoride and chloride. In order to reduce NOx emissions, denitration treatment of the flue gas after combustion must be performed. Currently, a selective catalytic reduction (SCR) flue gas denitration process is commonly used.

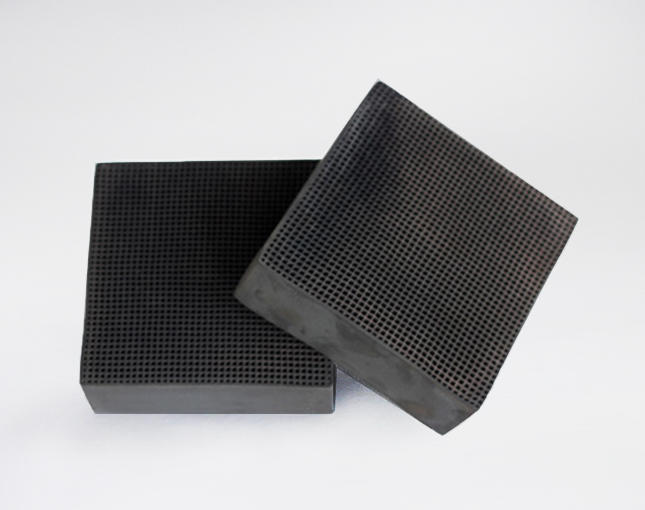

SCR DeNOx catalyst is made of honeycomb ceramics as a carrier and TiO2, V2O5, WO3 and the like as main active components. This type of catalyst has great advantages in terms of strength, anti-blocking, anti-wear and anti-poisoning. It is suitable for industries such as thermal power generation, waste incineration, nitric acid, nitrate, steel, chemical fertilizer and other industries.