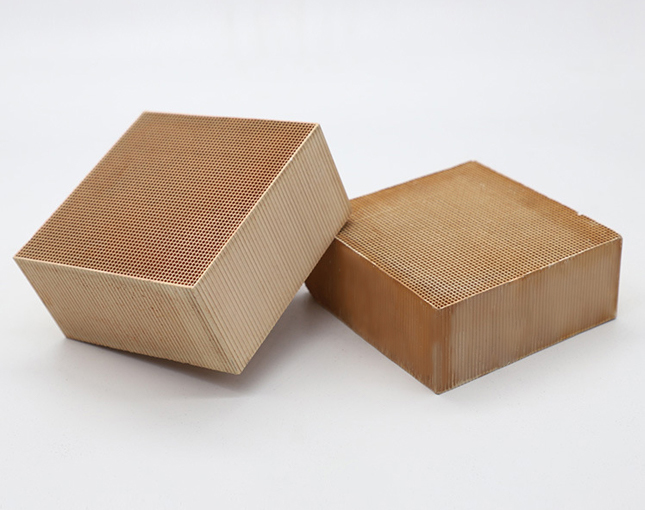

VOCs Treatment Catalysts for Industrial Exhaust Gas Purification

VOCs treatment catalysts for industrial exhaust gas purification, uses cordierite honeycomb ceramics as a carrier, and precious metals Pd and Pt (containing appropriate rare earth elements) as active components. It has the characteristics of high catalytic activity, good thermal stability, long service life, small airflow resistance, high strength and so on. This waste gas treatment catalyst can be widely used in organic waste gas treatment in chemical, paint, enameled wire, coating, oven and other industries.

Industrial organic waste gas purification treatment generally uses a low-temperature catalytic combustion method, and the harmful exhaust gas is subjected to catalytic oxidation-type flameless combustion, and the purification rate can usually reach more than 99%.

Process characteristics:

1. The catalyst has a wide application range and is suitable for treating industrial organic waste gas containing carbon monoxide, hydrocarbons and oxygen-containing derivatives thereof.

2. Low gas flow resistance, low reaction initiation temperature, high activity, and wide airspeed adaptation range. Under the conditions of organic matter exhaust gas concentration of 300 to 9000 mg / m3, space velocity of 5000 to 30,000 h-1, and reaction gas inlet temperature of 80 to 300 ℃, the purification effect is ≧ 95% (usually up to 99%).

3. The catalyst has good heat resistance, can work in the range of 350~600 ℃ for a long time, and can withstand short-term thermal shock at 900 ℃.

4. Long service life, no less than 8000 hours, the service life of the catalyst can be customized according to the user's service life requirements.

5. Low ignition temperature, no NOx compounds, and no toxic carcinogens such as benzopyrene and dioxin.

Application industries:

1. Automobile and machinery manufacturing industry, 2. Coating line and drying room, 3. Electronic manufacturing industry, 4. Printed circuit board (PCB), 5. Electrical manufacturing industry, 6. Enameled wire insulation, 7. Light industry, 8. Manufacturing Shoe coating, 9. Color printing in printing industry, 10. Metallurgical steel industry, 11. Carbon electrode production, 12. Chemical industry, 13. Chemical synthesis process (ABS synthesis), 14. Petroleum refining process, 15. Color steel manufacturing.Technical Parameters:

- Space velocity: ≥1×104 h-1

- Ignition temperature: 150°C-300 °C

- Optimal operation temperature: 300°C-500 °C

- Waste gas purification rate: ≥95

- Space velocity (h-1): 10 × 104

- Bulk density: 0.68±0.05g/mL

- Service life: 8000-16000 hours (1~2 years)

- Outlet Waste gas concentration: <100ppm