Fireplace & Oven Exhaust

A fireplace produces carbon monoxide when the combustion process is incomplete. Even with newly designed, manufactured models, including fireplace inserts, the combustion rate is not 100%; hence, CO is still produced.

As a source of carbon monoxide, fireplace models that run on natural gas are as equally dangerous as the wood burning type. Many natural gas fireplaces are sealed and vented directly to the exterior of the home, which greatly reduces the chance of CO poisoning.

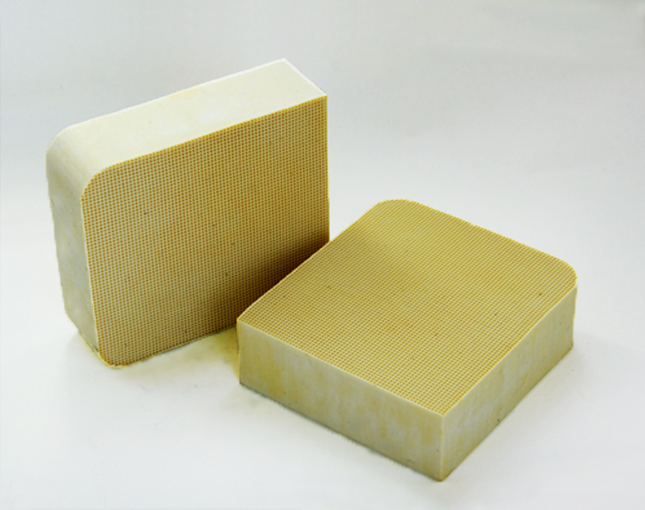

Luckily, carbon monoxide removal is possible through the process of catalysis. After the catalyst is installed, the exhaust gas discharged directly from the furnace during warming and the catalyst undergoes low-temperature catalytic oxidation to generate non-polluting carbon dioxide CO2 and water H2O, which serves the purpose of purifying the furnace exhaust gas.