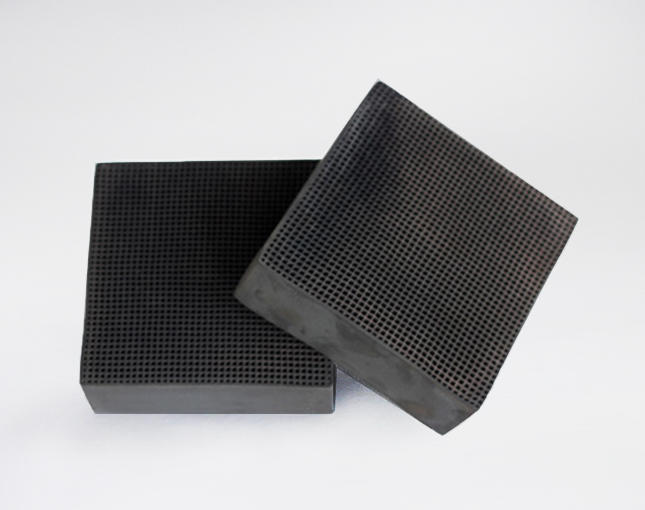

SCR Denitration (DeNOx) Catalyst

SCR DeNOx catalyst is made of honeycomb ceramics as a carrier and TiO2, V2O5, WO3 and the like as main active components. This type of catalyst has great advantages in terms of strength, anti-blocking, anti-wear and anti-poisoning. It is suitable for industries such as thermal power generation, waste incineration, nitric acid, nitrate, steel, chemical fertilizer and other industries.

Working principle:

The principle of SCR denitration is to use an appropriate SCR catalyst at a certain temperature (200-400 ° C) with ammonia as a reducing agent and use the selectivity of the reducing agent to preferentially react with nitrogen oxides to reduce it to nitrogen and nitrogen. water. The selective catalytic reduction method has higher efficiency and is a better technology that can be found widely and can be widely applied to fixed source NOx treatment.

The reduction of NH3Nox reaction as below:

Leading reaction:

6NO+4NH3→5N2+6H2O

6NO2+8NH3→7N2+12H2O

Second reaction:

8NO+2NH3→5N2O+3H2O

8NO2+6NH3→7N2O+9H2O

4NH3+3O2→2N2+6H2O

2NH3+2O2→N2O+3H2O

Technology Characteristics:

The temperature of SCR denitration reduction reaction is relatively low. The reduction reaction can be carried out in a temperature range of 200 ° C to 400 ° C. The reaction speed of denitration is fast and stable, and has the characteristics of low energy consumption. The efficiency of SCR denitrification can be as high as 95%, the ammonia leakage rate is less than 2 × 10-6, the NOx concentration in the tail gas is less than 100 ppm, and the normal operating temperature is about 300 ° C. The reaction requires the cooperation of a catalyst and a reducing agent, and the injection point is set to a single plane, which is suitable for various units.

Technical Parameters:

- NOX concentration: ≤5000ppm

- Reductive agent: Liquid ammonia, ammonia water or urea, led into as saturated gas

- Space velocity: 3000~10000 h-1

- Effective operation temperature: 150°C-420°C

- Optimal operation temperature: 260°C-300°C

- NOx conversion rate: ≥90%

- Service life: ≥2years

- Ammonia escape ratio: ≤30ppm

- Bulk density: 0.72±0.05g/mL

- Crushing strength: ≥14 MPa (Front), ≥4 MPa (Side)

- Coating loading: >8.0%

- Active Metal oxide loading: >9.0%

- Recommended installation Height/diameter ratio: Ceramic honeycomb 2:1; 1:1