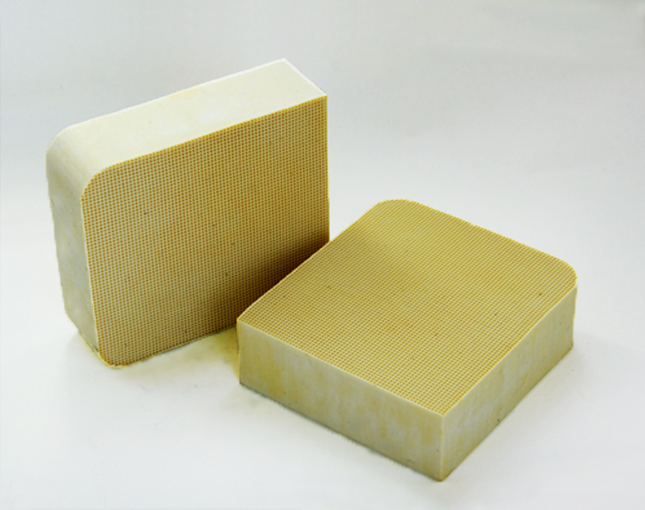

Carbon Monoxide (CO) Removal Catalyst (Honeycomb Ceramic Type)

The CO Removal Catalyst is made of cordierite honeycomb ceramics with a unique coating material and high content of noble metals Pd and Pt as active components. It can be used to remove carbon monoxide CO produced by incomplete combustion of various types of combustible gas. Under the conditions of temperature 150-200 ℃ and space velocity (0.3-1) * 104h-1, the carbon monoxide content of the purified gas can be reduced to below 0.5ppm; the oxygen absorption capacity of the catalyst can reach 50ml / g, which can catalyze carbon monoxide It reacts with oxygen to become carbon dioxide, and the catalyst can be regenerated.

Working principle: Before using the catalyst, it needs to be activated with fresh air or nitrogen to 180-200 ℃, and then pass in the gas to be treated. The temperature is above 200 ℃, and the operation is better, under the reaction conditions of 1.5 ~ 3.0 × 103h-1 Eliminate the CO in the CO gas to below 0.5ppm, the maximum heat resistance temperature is 750 ℃ (if the flammable gas concentration is high, a cooling system is required to prevent catalyst sintering), the mechanical strength is good, and the service life can reach more than 3 years.

Application field:

The catalyst can be used to remove a small amount of carbon monoxide in gases such as petroleum gas, inert gas, oxygen, etc. It can also be used in domestic natural gas water heaters, ovens, fireplaces and other equipment for catalytic combustion of incompletely burned CO with excellent purification effect.

Process characteristics:

① CO removal rate ≥98%;

② Precious metals Pd and Pt are active components, which can remove CO produced by insufficient combustion of various combustible gases;

③ Wide temperature range, effective catalysis between 150-750 ℃;

④ The service life can reach more than 3 years;

⑤ Compact structure and small use space, suitable for various equipment.

Technical Parameters:

- Space velocity: ≥3×103h-1

- Initial ignition temperature: 100°C-150°C

- Optimal service temperature: 180°C-200°C

- CO removal ratio: ≥ 98%

- Service life :≥ 2 years

- CO outlet content: <5ppm

- Bulk density: 0.68±0.05g/mL

- Crushing strength: ≥ 14 MPa

- Coating component: ≥10.0%

- Appearance: Usually is light yellow (would be grey after pre-reduction)