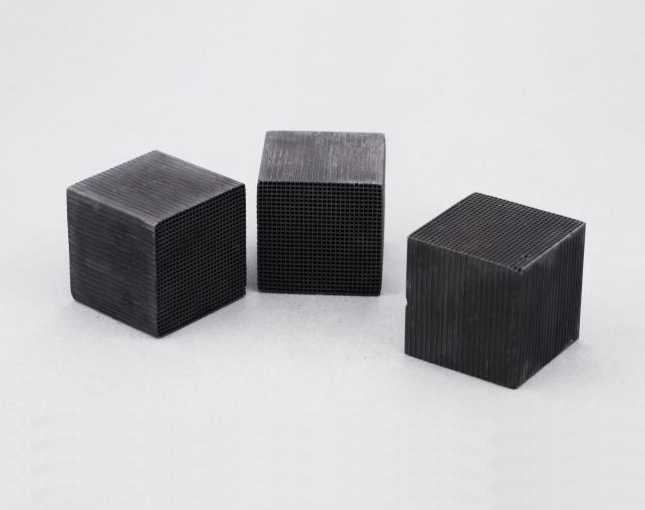

Low Concentration Ozone Decomposition Catalyst

Ozone decomposition catalyst takes honeycomb (foam) ceramic or γ type activated alumina as carrier, carrying specific rare earth auxiliaries and transition metal which performs excellent on decomposition capacity, moisture resistance, service life and other technical features. The catalyst can quickly decompose ozone into oxygen at room temperature, thereby eliminating the harm of ozone to the environment.

The catalyst is widely used in household appliances, photocopying, printing, synthesis of fine chemicals, and treatment of tap water and wastewater. Such as printing plants, ozone-type sterilization water disinfection machines (water purifiers, etc.), water plant ozone disinfection systems, ozone-type sterilization rooms, medical disinfection cabinets, urban communities using ozone treatment pipeline direct drinking water systems, hospitals using ozone sterilization, Sewage treatment system in chemical plant, production workshop with high-voltage discharge technology.

Process characteristics:

1. This type ozone decomposition catalyst is mainly used for ozonolysis of less than 300ppm, and can also treat about 1000ppm of ozone under relatively high humidity.

2. When the ozone decomposition catalyst is loaded into the reactor (or purifier) for use, the minimum thickness of the catalyst bed is 50mm, and the material of the container is required to be resistant to ozone corrosion.

3. After the catalyst has expired for a certain period of time (for example, about one year), after it is found that the catalyst activity has significantly decreased, the catalyst and desiccant can be taken out, dried in an oven at 100 ° C for 10 hours, and then refilled into the purifier.

4. For some industrial applications (such as waste water, exhaust water after purification of tap water), the temperature of the bed of the ozone decomposition catalyst can be increased by 50 to 90 ° C, which can significantly increase the service life of the catalyst.

5. The characteristics of honeycomb (foam) catalyst are that the wind resistance is relatively small, and the fine column catalyst has good humidity resistance.

Technical Parameters:

- Shape: Honeycomb (foam) ceramic, short column

- Size (mm): 100*100*50; 100*100*100, or customized; Ф (2~3) ×(5~10)

- Heap specific gravity (g / ml): 0.5~0.6

- Operating temperature: 20-30℃ or above, better at (50-90℃)

- Ozone decomposition ability: ≥95%

- Space velocity (h-1): 1 ~ 8 × 104

- Height-diameter ratio of catalyst bed: 1: 1, higher is better

- Service life: ≥8000 hours (one year)

- Purification depth of O3: ≤0.01 ppm